Enhancing Robotics Precision

Researchers employ OptiTrack to improve accuracy of mobile robots for adaptive automated assembly

RWTH Aachen University is the second largest technical university in Germany and a leading institution across Europe for its programs in science, engineering, and technology. The Laboratory for Machine Tools and Production Engineering (WZL) of RWTH Aachen University has a long history of pioneering research in the field of production technology. Established in 1906, the laboratory's work is focused on advancing fundamental theories while also applying findings to real-world industrial applications. The goal is to develop practical solutions that can be seamlessly integrated into production processes.

One of WZL's research areas includes the use of robotics within automated production and assembly environments. As consumer preferences increasingly shift toward product customization, WZL researchers are focused on ways to enhance the adaptability of robots on production floors.

"Manufacturing requirements for cars, ships, aircraft, and other products are becoming more tailored to individualized specifications," said Matthias Bodenbenner, WZL team leader of Interoperable Sensor Services. "This trend presents challenges in automating these assembly processes."

WZL Research Associate Guillaume Tréheux provided an example: "Consider a typical robotic arm in a fixed station—it can reliably repeat the same routine. However, this arm is not very adaptive to changes in the production system. For instance, if you want to paint a car a different color, the robotic arm could handle that without any issue. But assembling a completely different car with unique components is an entirely different challenge."

For automated processes to effectively adapt to such changes, a mobile robotic solution becomes more viable, according to Tréheux. "The key limitation, though, is that mobile robots—and especially automated guided vehicles (AGVs) or autonomous mobile manipulators (AMMs)—have low absolute accuracy," he said. This can result from factors such as localization challenges or uneven production floors, which can cause deviations from their intended movements, Tréheux explained.

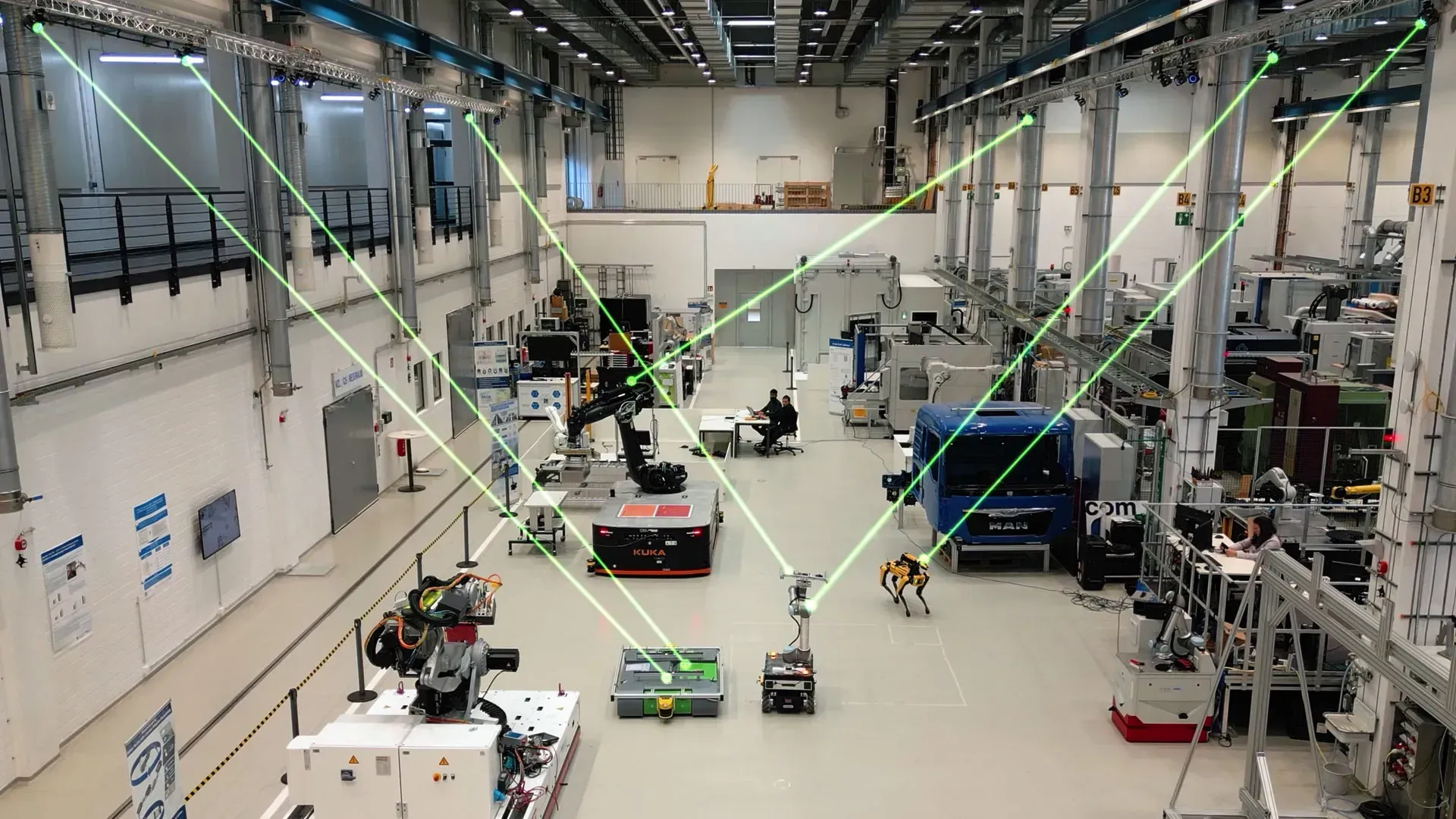

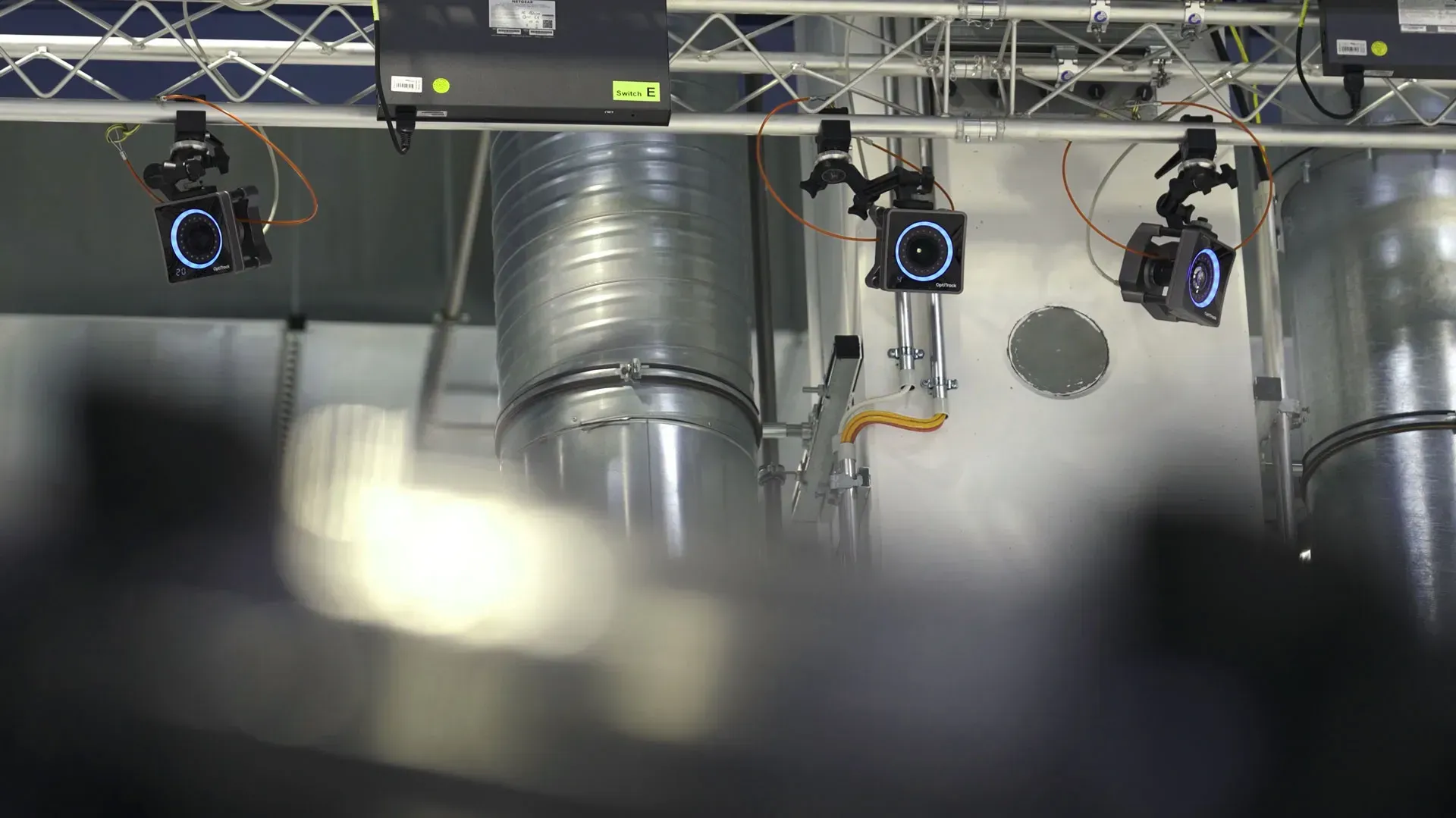

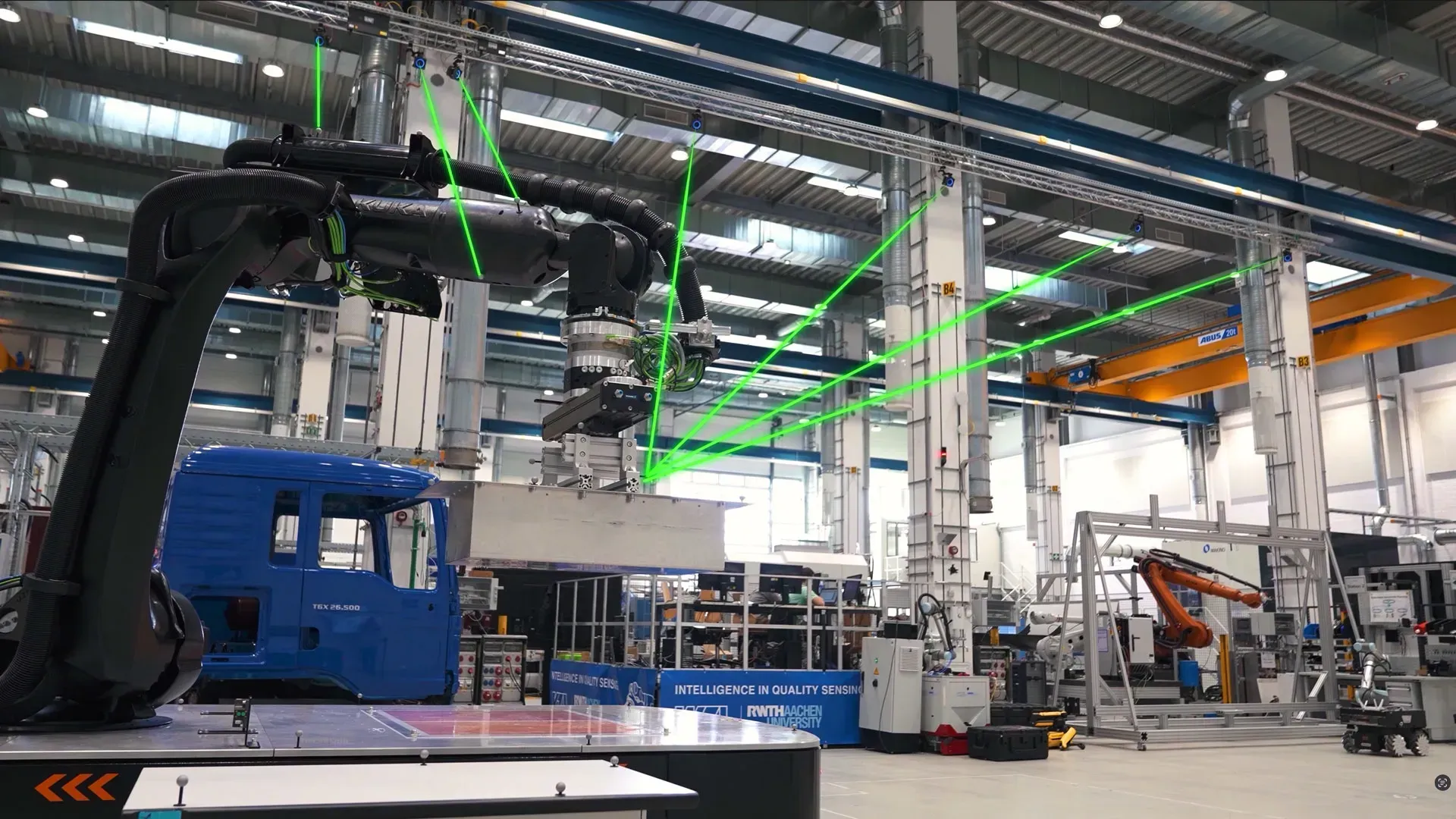

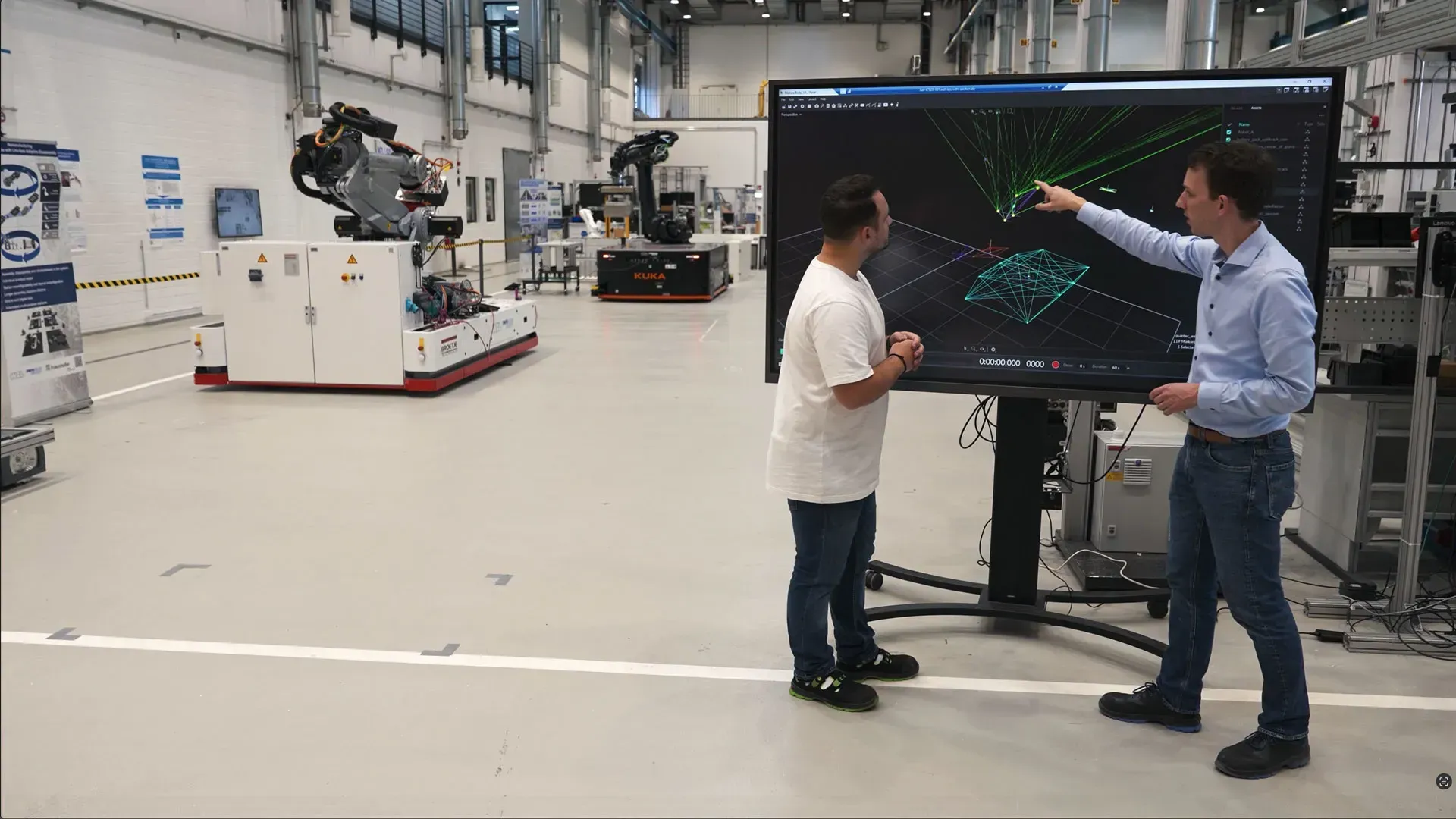

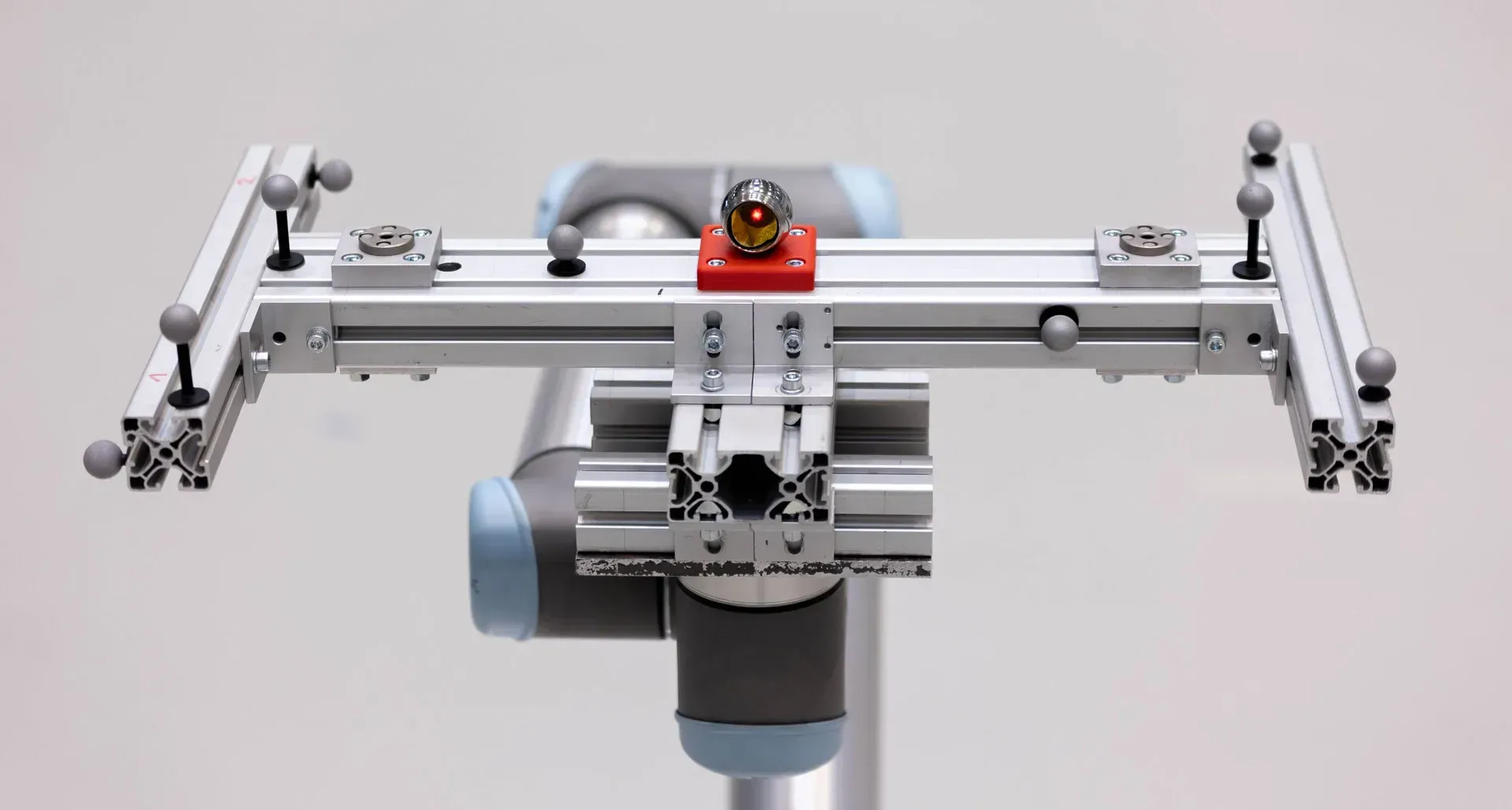

To enhance the accuracy of mobile robots in an automated production setting, the WZL laboratory integrated a large-scale OptiTrack motion capture setup featuring several PrimeX41 cameras. Combined with Motive software, the OptiTrack system captures precise positional data, which is relayed to a high-performance computing system controlling the robots.

"OptiTrack is a key part to our Industry 4.0 approach, where all components in our lab are connected and continuously provide data," Bodenbenner said. "With the OptiTrack system, we can collect precise data on the robots' location, movement, speed and other critical factors. This knowledge is essential for continuously refining the robots' movements, enabling them to complete tasks in the required accuracy."

Synchronization

Motion capture tracking is crucial for enabling robotic precision in flexible assembly steps, according to the WZL researchers, whether it involves operating small tools like a screwdriver or handling large components such as airplane exterior paneling — where rigorous safety standards and exceptionally stringent tolerances are necessary due to the criticality of the product.

For the assembly floor, OptiTrack with Motive software emerged as the preferred option due to its accuracy and the higher level of flexibility it provides compared to other systems. "OptiTrack is not limited to tracking only one target at a time," Bodenbenner said. "Instead, we can track multiple robots simultaneously."

This capability allows the researchers to precisely coordinate the robots' movements in relation to one another, enabling them to work together in synchronization. "By parallelizing robotic workflows, we can potentially improve the efficiency of automated processes," Tréheux said.

Download PDF

Click the link to download a PDF of this customer story: https://optitrack-documents.s3.us-west-2.amazonaws.com/OptiTrack_Case-Study_Laboratory-for-Machine-Tools-and-Production-Engineering-(WZL).pdf

About OptiTrack

OptiTrack is a worldwide leader in 3D tracking technology, offering cutting-edge solutions renowned for accuracy and reliability. With a comprehensive range of high-performance cameras, software, and accessories, OptiTrack supports a diverse group of users ranging from entertainment and biomechanics to research and ground truth robotics. From capturing the subtle nuances of human movement to tracking complex interactions in virtual environments, OptiTrack technology empowers users to track, analyze, and visualize motion data with unprecedented detail. Whether it's providing training or offering guidance on system optimization, OptiTrack is your partner in pushing the boundaries of what's possible, empowering innovation across the globe.